3D Printing Redefines A New Industrial Revolution

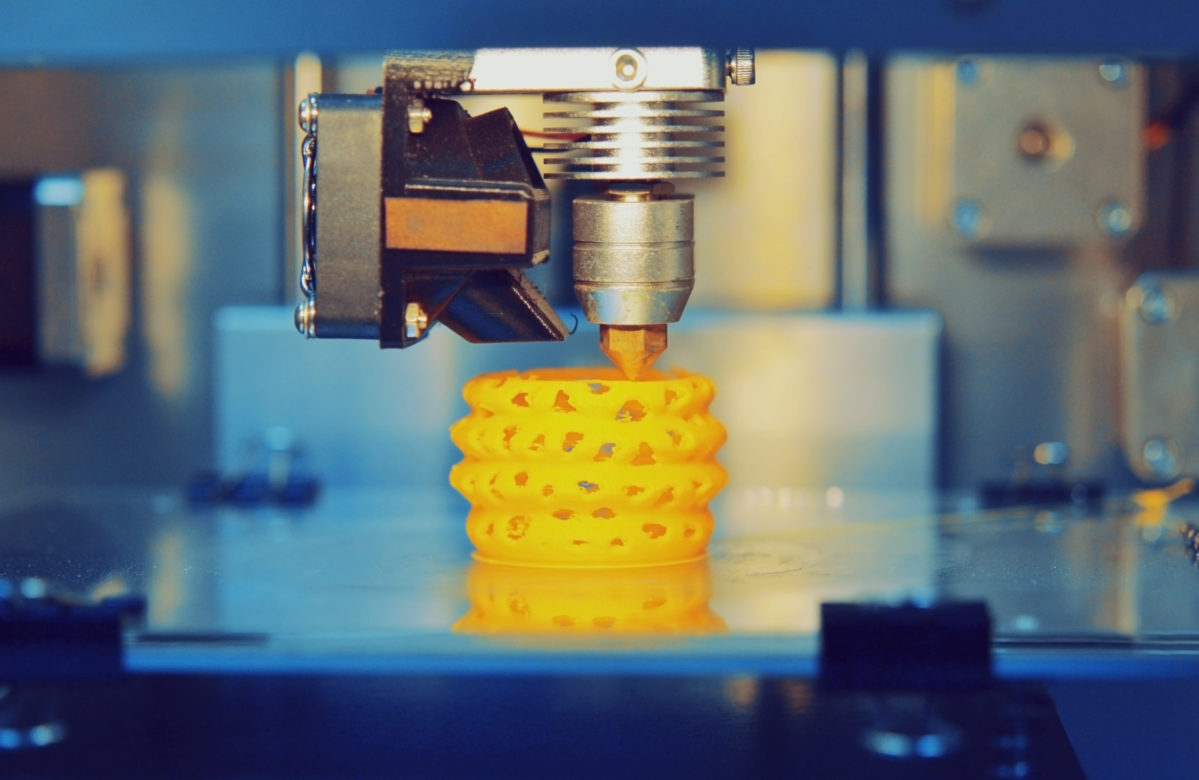

The world is on the cusp of a new industrial revolution, and it’s being built layer by layer. Once a niche technology confined to rapid prototyping labs, 3D printing, or additive manufacturing, has evolved into a powerful force that is redefining how we design, create, and produce almost everything. This transformation is driven by breakthroughs in materials science, a significant reduction in cost, and the integration of artificial intelligence and automation. The process of building objects from the ground up, rather than carving them out of a larger block, is not just more efficient; it is unlocking a world of creative possibilities and solving some of the most complex manufacturing challenges. This article will delve into the game-changing advancements that are redefining 3D printing, exploring its disruptive applications across industries, the technologies powering its growth, and the profound impact it will have on supply chains, sustainability, and our daily lives.

The Evolution of a Technology

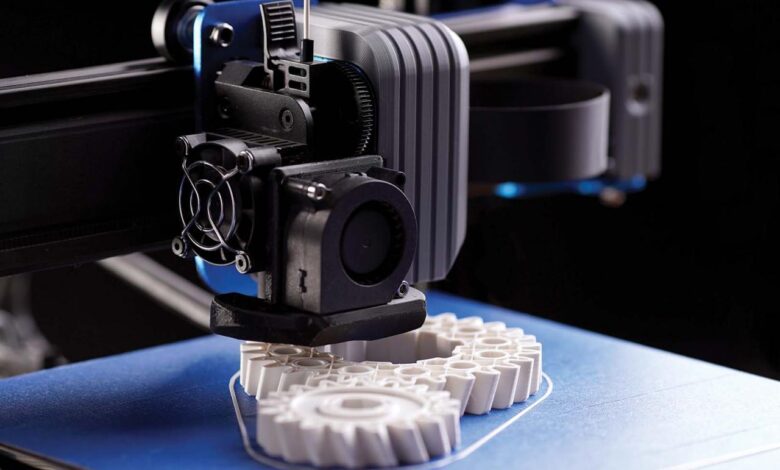

The early days of 3D printing were defined by slow, expensive machines that produced fragile plastic objects. The new era is characterized by an incredible leap in speed, precision, and the variety of materials that can be used.

A. Advanced Materials

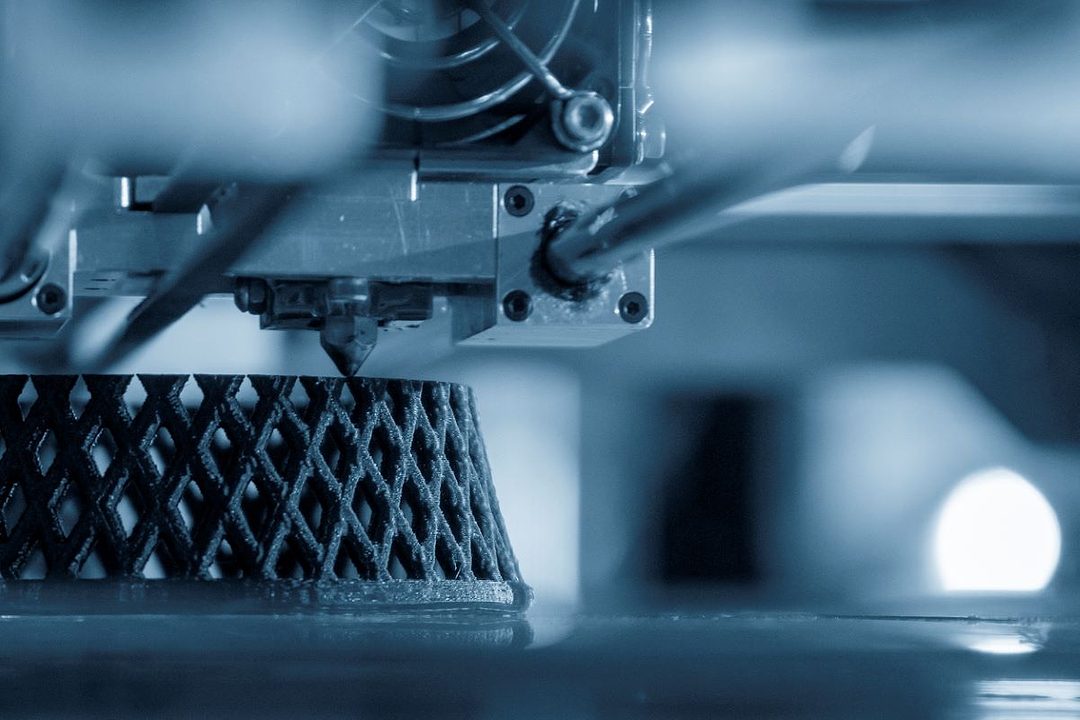

The true power of modern additive manufacturing lies in the materials it can now use. What was once limited to basic plastics has expanded to a vast range of industrial-grade materials.

- Metals: High-quality metal parts can now be printed using a variety of techniques, including laser sintering and electron beam melting. This is a game-changer for industries like aerospace and automotive, where strong, lightweight, and complex metal components are essential.

- Composites: 3D printing can now incorporate carbon fibers and other composites directly into a part as it is being built. This results in parts that are incredibly strong and light, perfect for applications in high-performance sports equipment and defense.

- Ceramics: Advanced ceramic materials can now be printed, opening up a world of possibilities for applications in electronics, high-temperature engineering, and even art.

- Biological Materials: In the field of bioprinting, scientists are using 3D printers to create human tissues and even organs, using a “bio-ink” made of living cells. This is a revolutionary step toward personalized medicine and organ transplantation.

B. The Rise of Hybrid Manufacturing

The future of manufacturing isn’t just about 3D printing alone. It’s about combining the best of both worlds. Hybrid manufacturing integrates additive and subtractive technologies (like CNC milling) into a single machine.

- Efficiency and Precision: A hybrid machine can print a near-net-shape part and then use a CNC mill to precisely finish the surfaces and add features that cannot be printed. This reduces waste, cuts down on production time, and results in a higher-quality finished product.

- Repair and Remanufacturing: Hybrid systems can be used to repair damaged parts by adding new material and then machining it back to its original shape. This extends the lifespan of expensive components and reduces waste.

Applications Across the Board

3D printing is no longer a tool for a single industry; its versatility and precision are making it a disruptive force across a wide range of sectors.

A. Aerospace and Automotive

The ability to create complex, lightweight, and incredibly strong parts is a perfect fit for the aerospace and automotive industries.

- Aerospace: 3D printing is used to create complex engine components, lighter structural parts, and specialized tools. For example, a single, 3D-printed part can replace dozens of individual components, reducing weight, simplifying assembly, and cutting costs.

- Automotive: Car manufacturers are using 3D printing for everything from creating customized interior parts and dashboard components to printing complex exhaust manifolds and even entire car chassis. This allows for rapid iteration and a new level of design freedom.

B. Healthcare

3D printing is at the heart of the personalized medicine revolution, creating products that are tailored to an individual’s unique anatomy.

- Custom Prosthetics and Implants: Patients can receive custom-fitted prosthetics, dental implants, and surgical guides that are perfectly matched to their body, leading to a better fit, improved comfort, and faster recovery times.

- Surgical Planning: Surgeons can print a precise, 3D model of a patient’s organ or tumor. This allows them to practice a complex procedure on a realistic model before going into the operating room, reducing the risk of complications.

- Pharmaceuticals: Researchers are experimenting with 3D printing to create customized pills with precise dosages and unique release profiles. This could lead to more effective and personalized drug delivery.

C. Construction and Housing

Additive manufacturing is even changing how we build our homes and infrastructure.

- Rapid Housing: 3D printing is being used to construct homes and buildings quickly and affordably. Large-scale robotic printers can lay down layers of concrete or other materials, building the walls of a house in a matter of days.

- Complex Structures: Architects and engineers are using 3D printing to create highly complex and organic building forms that would be impossible to achieve with traditional construction methods.

- Sustainable Building: 3D printing can reduce construction waste by only using the materials needed for a specific structure. It can also use sustainable materials and recycled aggregates.

The New Industrial Revolution

The redefining of 3D printing is not just a technological shift; it is a fundamental change in how we think about production, supply chains, and sustainability.

A. On-Demand and Distributed Manufacturing

The traditional manufacturing model relies on large, centralized factories and complex global supply chains. 3D printing enables a new model of on-demand and distributed manufacturing.

- Reduced Inventory: Instead of stockpiling parts and products, companies can simply print them as needed. This reduces the need for warehousing and cuts down on waste.

- Local Production: Parts can be printed at the point of need, reducing the need for long-distance shipping and its associated carbon footprint. This makes supply chains more resilient and responsive to demand.

- Mass Customization: 3D printing makes it just as easy to produce a unique, customized part as it is to produce a thousand identical ones. This unlocks a new era of personalized products, from custom-fit shoes to unique architectural features.

B. Sustainability

3D printing is inherently more sustainable than traditional manufacturing.

- Reduced Waste: Additive manufacturing uses only the material needed to build a part, minimizing waste compared to subtractive manufacturing processes that cut away from a larger block.

- Lighter Products: By creating complex, lightweight geometries, 3D printing can reduce the weight of products like cars and airplanes, leading to significant fuel savings.

- Circular Economy: 3D printing can use recycled materials and enables the repair and remanufacturing of old parts, making it a key component of a circular economy.

Challenges and Opportunities

Despite the incredible progress, 3D printing still faces significant challenges that need to be addressed to realize its full potential.

A. Quality Control and Standardization

Ensuring the quality and consistency of 3D-printed parts is a major hurdle. The layer-by-layer nature of the process can introduce subtle imperfections. There is a need for:

- Real-time Monitoring: The use of sensors and AI to monitor the printing process in real-time, detecting and correcting flaws as they happen.

- Standardized Protocols: The industry needs to develop and adopt standardized testing and certification protocols to ensure the reliability of 3D-printed parts.

B. Intellectual Property and Security

The ease of replicating digital designs raises new questions about intellectual property rights. It is just as easy to print a patented design as it is to download a movie. Furthermore, the digital nature of the process makes it vulnerable to cyberattacks, where a hacker could introduce flaws into a digital file, leading to a compromised part.

C. The Digital Divide

The full benefits of this technology will only be realized if it is accessible to all. There is a risk of a new “digital divide,” where only a few wealthy nations and corporations have access to this transformative technology. Governments and educational institutions must work to ensure that training and resources are widely available.

Conclusion

3D printing, once a niche technology for hobbyists and engineers, is no longer a novelty; it is the cornerstone of a new industrial revolution. The incredible advancements in materials science have unlocked a world of possibilities, from printing high-strength metal parts for jet engines to creating living human tissues in a lab. The convergence of additive and subtractive manufacturing in hybrid systems is blurring the lines between traditional and modern production, creating more efficient and powerful ways to create. This is not just a story of technological progress; it is a fundamental shift in how we approach production itself. The move towards on-demand and distributed manufacturing is poised to disrupt global supply chains, making them more resilient, responsive, and sustainable. By enabling local production and reducing the need for massive inventory, 3D printing is not just cutting costs; it is also significantly reducing the environmental footprint of production.

However, the journey to a fully realized 3D-printed world is not without its hurdles. Ensuring consistent quality control, establishing new standards for certification, and addressing the complex issues of intellectual property and cybersecurity are critical challenges that require collaboration across industries and governments. Furthermore, as with any transformative technology, we must ensure that its benefits are not concentrated in the hands of a few but are accessible to everyone, fostering a more equitable and innovative global economy. The era of 3D printing is here, and its promise extends far beyond a simple machine that creates objects. It is a tool for innovation, a catalyst for sustainability, and a key to a new era of personalized, efficient, and resilient manufacturing. We are no longer just building things; we are redefining the very act of creation, one layer at a time.